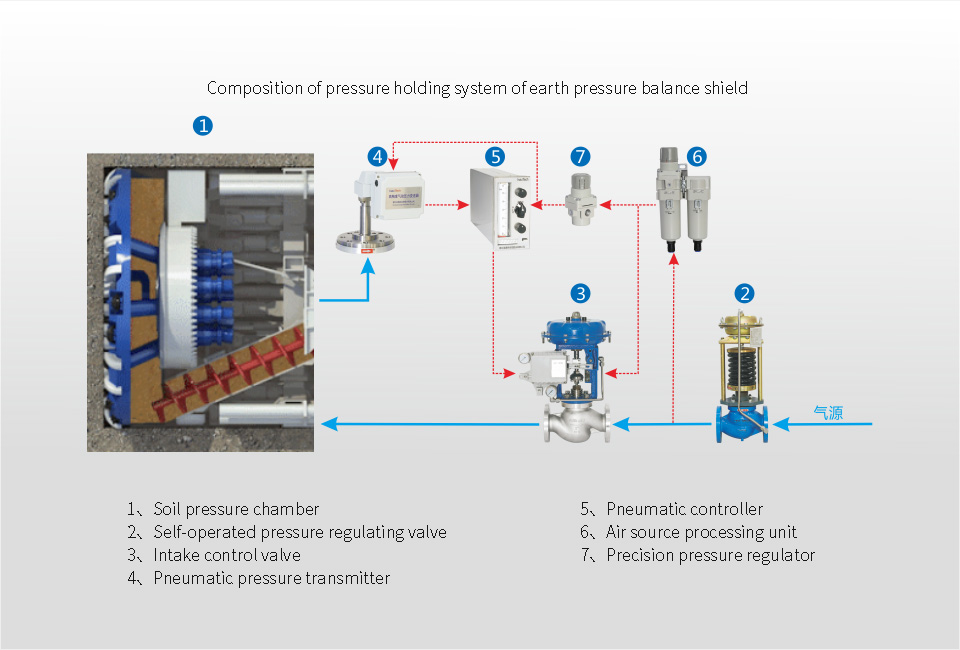

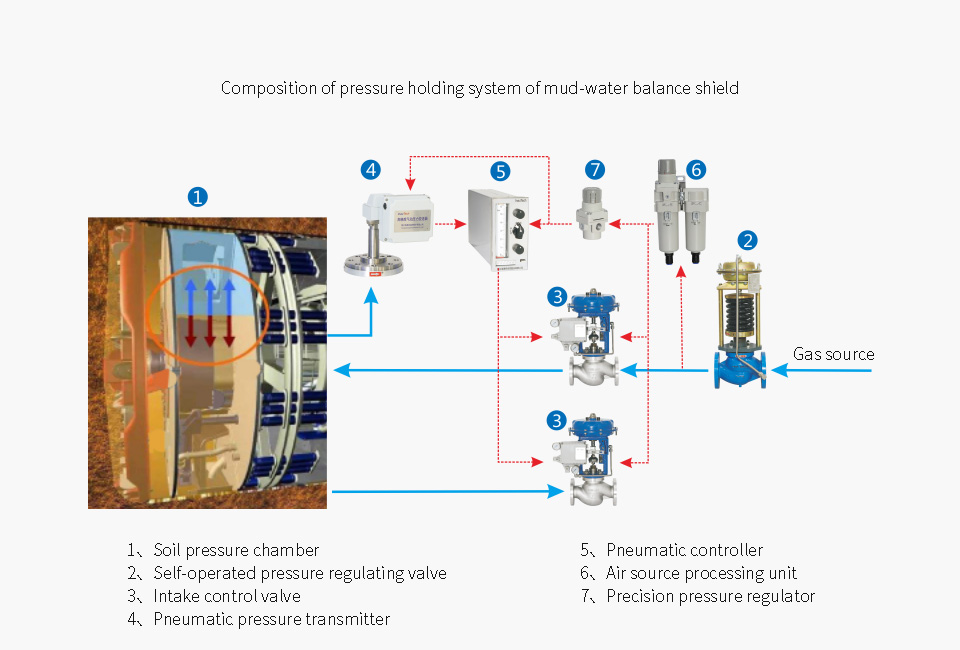

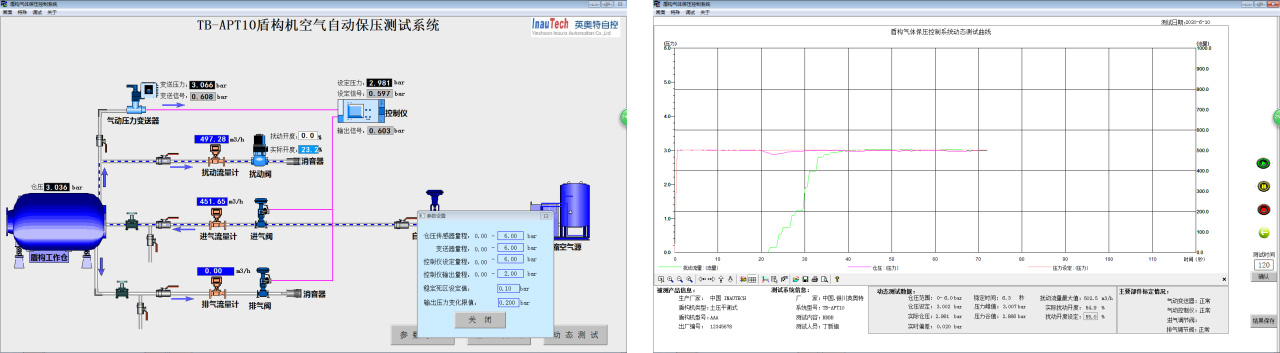

At present, the mechanical excavation of tunnels mainly includes two types of shield technology: earth pressure balance and mud-water balance. The greater risk of shield construction in soft soil is that the pressure on the face of the tunnel is not Stable and mutation. Maintaining the stability of the tunnel face through the compressed air automatic adjustment and holding pressure control system (shield machine air automatic holding pressure system) is currently one of the commonly used methods in shield equipment. During construction, air control technology is used to control the tunneling surface The pressure is automatically adjusted and controlled so that it is always in a balanced state to ensure the stability of the excavation surface during shield tunneling, thereby ensuring safe and efficient shield construction. The air automatic pressure maintaining system of the shield machine is a single parameter fixed value closed-loop automatic control system with the soil bin or mud bin as the controlled object and the pressure in the bin as the controlled parameter.

The proportional integral (PI) regulation law is realized through pure pneumatics. The proportional action can speed up the control process and reduce the dynamic deviation; and the integral action can eliminate the residual error. The PI parameter adjustment range is large, the accuracy is high, and the adjustment is convenient. The adjustment control accuracy is up to ±1%.

Based on the force balance working principle, with feedback design concept, because of the small displacement, small friction loss, the adjustment instrument response is sensitive, high precision, compact structure, not easily affected by environmental temperature, and strong anti-interference ability.

The output signals of the pneumatic regulating instrument are all amplified by the power amplifier in two stages of pressure and flow, which can be transmitted over a long distance.

The pressure holding system comes with a given pressure, actual pressure indicating instrument, and a control instrument output signal indicating instrument, realizing real-time monitoring and facilitating on-site adjustments.

It has a "hand/auto" non-disturbance switching function for on-site debugging and emergency treatment.

The pneumatic adjustment instrument has a full metal shell with high protection level and is suitable for harsh on-site working conditions.

Using dedicated calibration and testing equipment, accurate calibration according to customer requirements.

Customized design and development can be carried out according to the special needs of customers and working conditions and environmental requirements.

Professional and directional engaged in the design and development of shield pressure holding system;

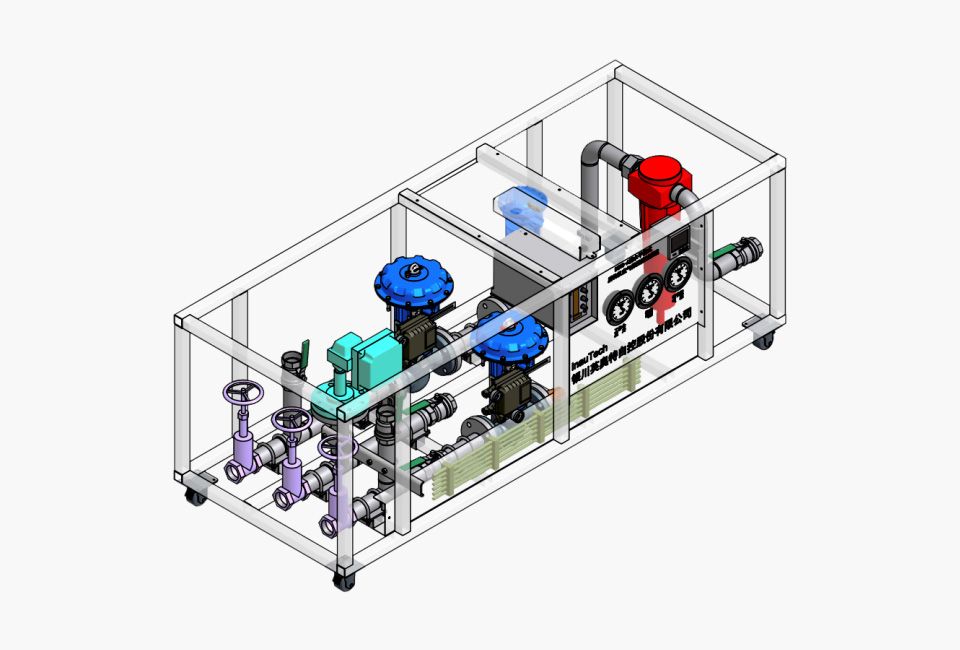

Customized design can be made according to shield machine construction and supporting needs, such as: mobile shield pressure holding system;

Provide 24-hour technical consultation, model selection and quotation services;

Original maintenance, testing, and calibration test equipment to ensure service and product quality;

Hundreds of sets of pressure-holding system adjustment and maintenance project experience, we design products, and are familiar with the site at the same time.

The object to be adjusted in the automatic air pressure holding system of the shield machine. The purpose of the automatic air pressure holding system of the shield machine is to keep the air pressure (adjusted parameter) in the earth pressure/sludge tank always equal to the given pressure of the pneumatic controller.

|

①Self-operated pressure regulating valve: Automatic adjustment is realized by using the pressure change of the medium (compressed air) to be adjusted. The pressure adjustment type behind the valve is adopted to stabilize the air source, maintain a constant pressure in front of the intake control valve, and ensure the stable operation of the pressure holding system. Advantages: No additional energy is needed, and it can work in the absence of electricity and gas, which is convenient and energy-saving; Adjustment accuracy 5%~10%; The valve trim is designed with a pressure compensation device to eliminate the influence of pressure fluctuations on the accuracy of the set point, and the adjustment is more stable; The range of pressure setting points is fine and interlaced to meet the needs of various working conditions and is easy to select; The pressure setting is convenient, and it can be set continuously without interference during operation, and it can be used without maintenance; Equipped with a dedicated pressure connector, the installation is simpler and more reliable. |

|

②Inlet/exhaust regulating valve: The actuator unit in the shield pressure holding system is controlled by the output command (signal) of the controller to inflate and exhaust the soil pressure/sludge tank respectively. Advantages: Equipped with air/air valve positioner, it can realize split-range control and achieve high-precision adjustment control; Pneumatic film actuator with independent intellectual property rights, better air tightness, soft work, sensitive adjustment and high reliability; New V-shaped stuffing box structure, superior sealing performance; The valve core/seat is hardened (>58 Rockwell hardness), it is resistant to erosion, can adapt to harsh working conditions, and greatly improves the service life; The leakage level of the regulating valve can reach VI, and the pressure holding system runs more stable. |

|

③Pneumatic pressure transmitter: The transmitter unit of the shield pressure holding system converts the earth pressure/air pressure in the mud water tank (adjusted parameter) into a proportional pressure signal of 0.02~0.1MPa (0.2~1bar). Advantages: Specialized customization for the shield pressure holding system, with sensitive response, high precision, compact structure, not easily affected by ambient temperature, and strong anti-interference ability; The basic error is not more than 1% of the full range, and the sensitivity is not more than 0.1% of the range; The output signal is amplified by two stages of pressure and flow through a power amplifier, which can be transmitted over a long distance; Flange installation avoids the blockage of the pressure pipe. Good adaptability to working conditions, better transmission accuracy and stability. |

|

④Pneumatic controller: Integrating the functions of a given unit, a display unit, and a regulator, it compares the measurement signal sent by the pneumatic pressure transmitter with the given signal, and amplifies the obtained deviation signal according to the proportional integral regulation law, and then outputs a corresponding The control signal to command the intake/exhaust regulating valve. Advantages: Realize the proportional integral (PI) regulation law, the proportional action can speed up the control process and reduce the dynamic deviation; and the integral action can eliminate the residual. The PI parameter adjustment range is large, the accuracy is high, and the adjustment is convenient. Adjust and control accuracy up to ±1%; Comes with a given pressure, actual pressure indicating instrument, and a control instrument output signal indicating instrument, realizing real-time monitoring and convenient on-site adjustment; With "hand/auto" non-disturbance switching function, used for on-site debugging and emergency treatment; The output signal is amplified by two stages of pressure and flow through a power amplifier, which can be transmitted over a long distance; The front size of the meter is small, which is convenient for dense installation. |

|

⑤Air source processing unit: Two-stage filtration is performed on the air source, and the pressure is reduced to the rated pressure required by the regulating valve. Advantages: The filtration accuracy reaches 0.01μm, which guarantees the quality of the air source and meets the requirements for the use of pneumatic regulating instruments; With metal cup, excellent protection performance and environmental resistance performance. |

|

⑥Precision pressure regulating valve: Adjust the air source pressure for the second time, and adjust the air source pressure to 0.14 MPa required by the pneumatic pressure transmitter and the pneumatic controller. Advantages: Sensitive response and high adjustment accuracy; The air consumption is small, energy is saved, and air supply is guaranteed. |