According to customers' automation control needs, we provide customers with integrated automatic control solutions, including equipment (field instruments, valves, control systems) selection, on-site installation and commissioning, test runs, operation services, etc. We not only provide automation control solutions for the process, but also can monitor the operating status of the user's important equipment online, and provide reference suggestions for the maintenance of the equipment. For example, testing and analyzing moving equipment: the operating efficiency of fans, pumps, stirring and other equipment, the output status, and the working status of static equipment such as heat exchangers and reactors, timely or in advance, give equipment maintenance suggestions. In addition, through the comprehensive analysis of system data, the system's energy consumption, output, and the quality of finished products are calculated to protect the optimization and analysis of process operation.

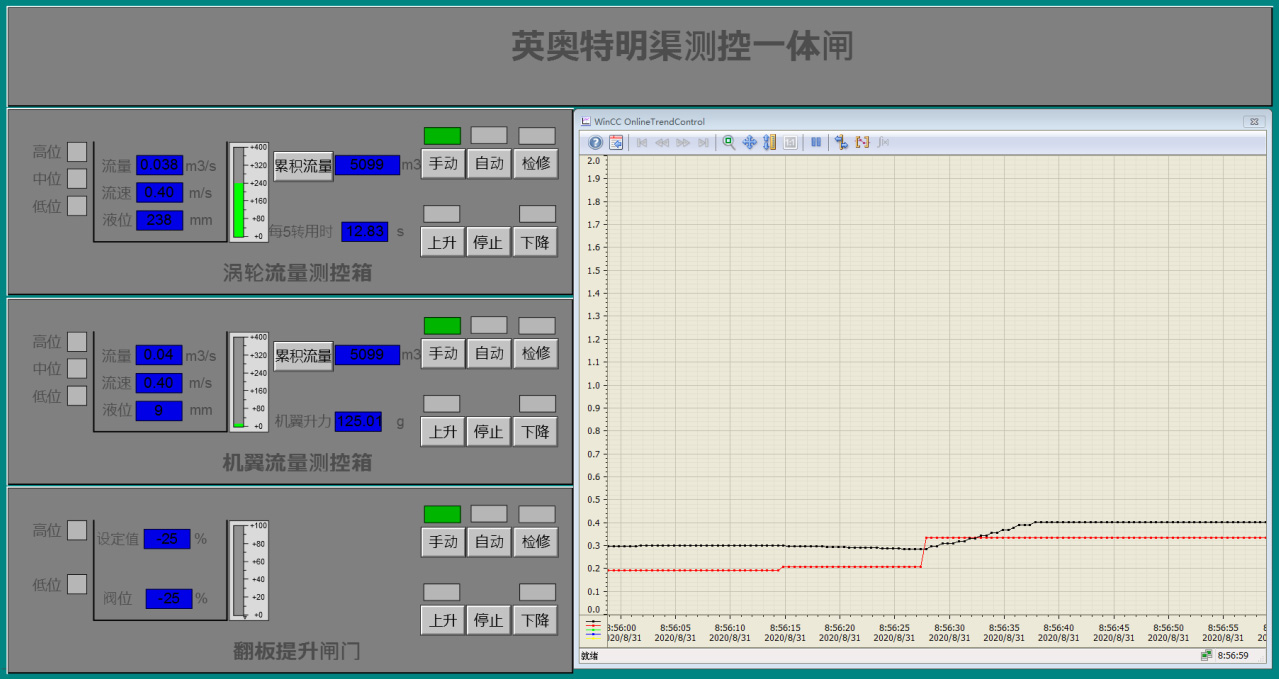

The automatic control system of open channel measurement and control gate is specially designed for agricultural irrigation management. The product integrates user management, water management, gate management, and wireless data transmission to achieve intelligent irrigation control. Wireless transmission of irrigation water information to the network server. It makes it possible for the control center to perform big data statistics and analysis of water resources, and successfully solve the long-standing problems of difficult water metering, irrigation fees, and waste of water resources in agricultural irrigation management.

The integrated open channel measurement and control gate mainly includes: automatic flap gate valve, flow measurement box, solar power supply system, remote communication system and other parts. The automatic flap gate adopts a unique 2-action mechanism, which effectively solves the problem of tight valve closing and preventing the channel from being blocked by sediment. At the same time, the mechanical limit mechanism and electrical limit are used to ensure the normal and reliable operation of the gate. The installation and adjustment of the gate are convenient, simple and easy to maintain.

The flow measurement box is mainly aimed at the characteristics of channel media with high sediment content and low flow velocity. The unique flow sensor can measure fluid with a flow velocity of less than 0.1m/s, and the measurement accuracy can reach 2%. Liquid level measurement adopts displacement encoder, the measurement is accurate, and the accuracy can reach 1mm.

The above equipment adopts low power consumption, anti-violent damage design, and can operate reliably in the field environment for a long time.

Industrial automation complete system design;

PLC system programming and on-site installation and debugging;

Programming and debugging of configuration software such as Kingview and wincc on the upper computer;

Automation project upgrade, technical support;

Automated product maintenance;

Customized design of intelligent control cabinet based on PLC system, etc.

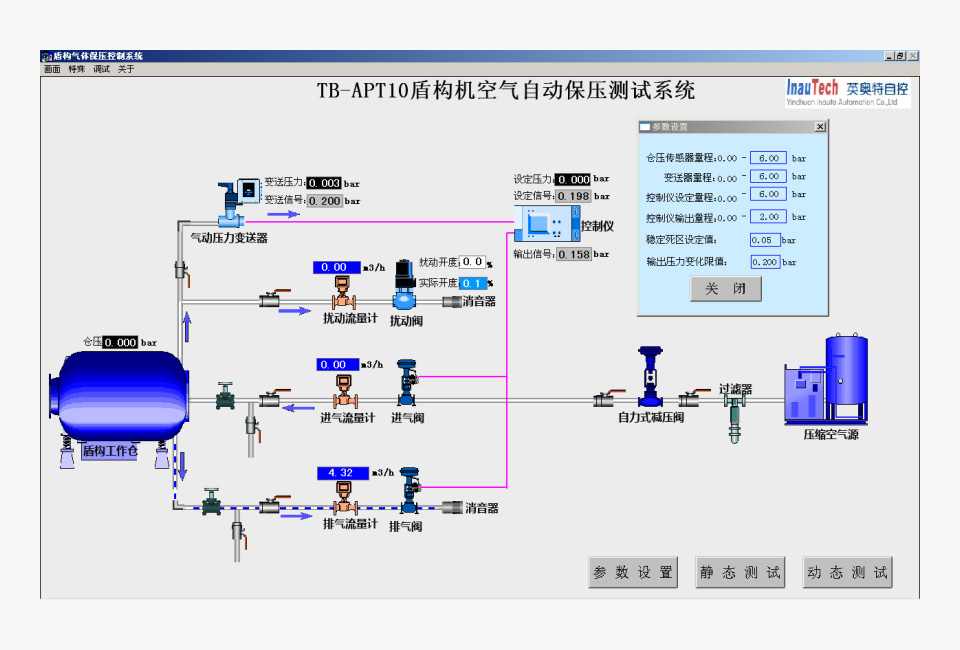

The automatic pressure holding device detection system of the shield machine samples the intake control air pressure, working chamber pressure, and exhaust air pressure with electrical signals, converts the performance parameters of the pressure holding device, and displays them dynamically and intuitively with various curves. , Which greatly facilitates the adjustment and troubleshooting of the pressure holding system.

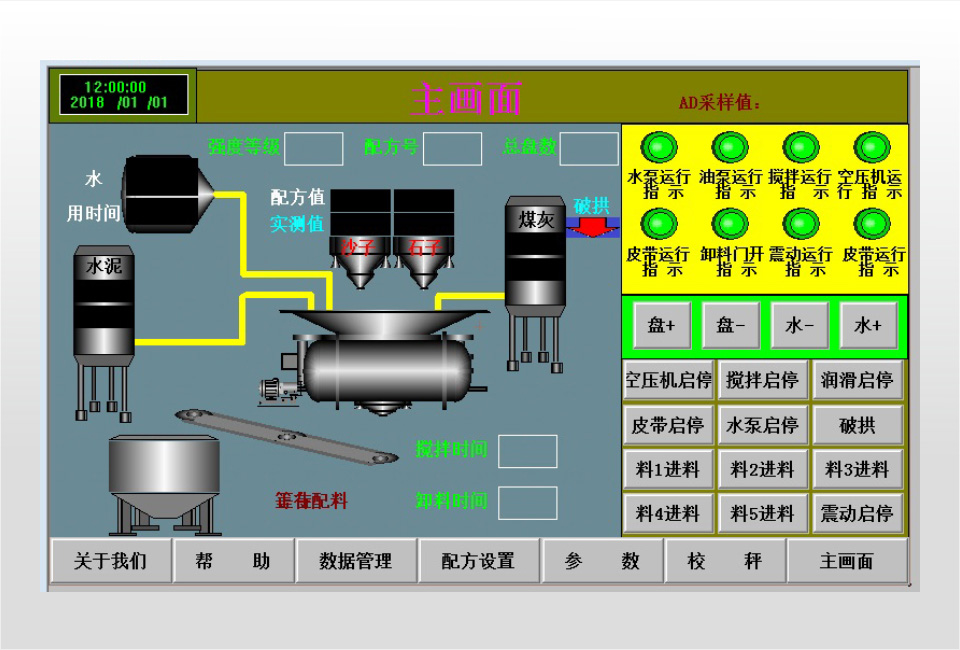

The system is designed according to customer needs, and it is easy to set up communication with the lower-level equipment, without the need to re-develop the code, which greatly reduces the user's dependence on software developers and is easy to maintain. Integrate various information management of concrete mixing plant ERP.

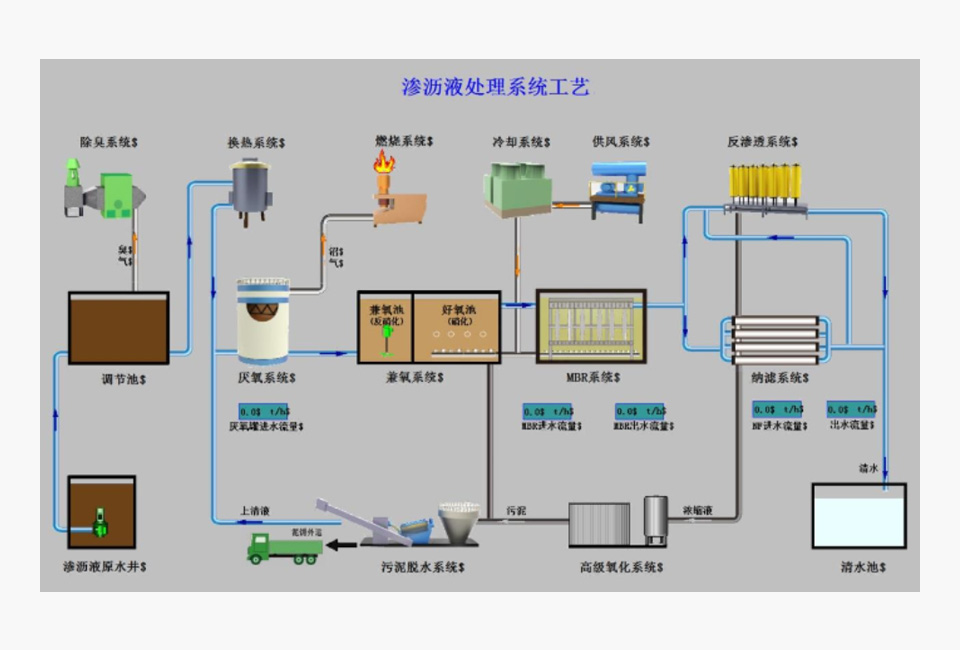

According to the scale and characteristics of the treatment plant, the principle of centralized monitoring as the mainstay and decentralized control as the auxiliary is adopted. The control system is equipped with signal alarm and interlocking protection facilities. The whole control system is divided into three levels of control layers: equipment on-site manual, PLC substation on-site monitoring and remote monitoring in the central control room.