Soft seal ball valve is mainly used in natural gas, oil, chemical, metallurgy, urban construction, environmental protection, pharmaceutical, food and other industries. Sulfur resistant series products are suitable for long-distance natural gas pipelines with hydrogen sulfide medium, many impurities and serious corrosion.

The structural characteristics of soft seal ball valve are as follows: < br / > 1

Unique valve seat sealing structure: the soft sealing ball valve adopts the structure design of double inclined plane elastic sealing ring or V-groove elastic sealing ring to ensure the reliability of sealing. For the ball valve under low pressure, ultra-low pressure or vacuum conditions, the valve seat sealing structure loaded with leaf spring is adopted to ensure the long-term reliable sealing of the ball valve. Medium and high temperature ball valve seat material can choose para polyphenylene or metal material.

Automatic pressure relief structure: when the pressure in the middle cavity rises abnormally, the medium in the middle cavity can push the valve seat by its own thrust to release the pressure automatically, so as to ensure the safety of the valve body.

Fireproof structure: according to the working conditions and the needs of users, the ball valve can be designed as fireproof structure. The fire resistance design of ball valve shall comply with the provisions of API 607, API 6fa and JB / T 6899.

Anti static structure: when working, due to the friction between the insulating medium and the ball, electrostatic charges will be generated and accumulated on the ball. In order to prevent electrostatic sparks, an anti-static device is set on the valve to export the charges accumulated on the ball.

Locking device: a lockable structure is designed at the fully open and fully closed positions of the manual ball valve to prevent improper operation and unexpected line vibration.

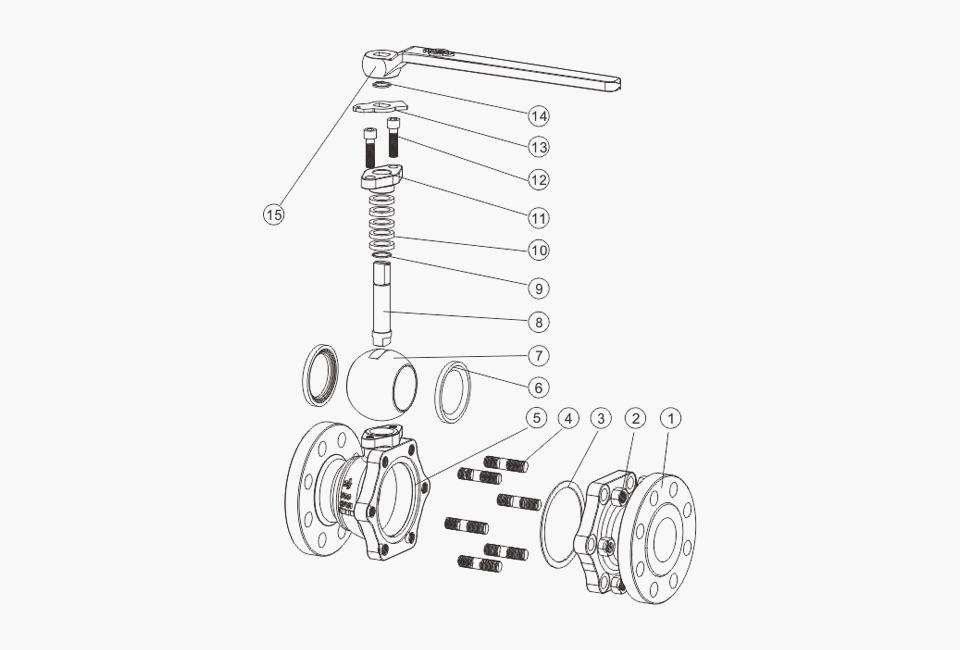

| Number | Part name | Material | |

| GB | ASTM | ||

| 1 | Valve cover | WCB | A216-WCB |

| 2 | Nut | 35 | A194-2H |

| 3 | Shim | Flexible graphite + stainless steel | Flexible graphite + stainless steel |

| 4 | Stud | 35CrMoA | A193-B7 |

| 5 | Valve body | WCB | A216-WCB |

| 6 | Valve seat | PTFE | PTFE |

| 7 | Sphere | 304 | 304 |

| 8 | Stem | 1Cr13 | A182-F6a |

| 9 | Shim | PTFE | PTFE |

| 10 | Filler | Flexible graphite | Flexible graphite |

| 11 | Packing gland | WCB | A216-WCB |

| 12 | Screw | 35 | A194-2H |

| 13 | Positioning film | Q235A | Carbon steel |

| 14 | Retaining ring | 65Mn | AISI 1566 |

| 15 | Handle | KT330-08 | A47-667 32510 |

| Pressure | 1.6~42.0MPa | Class 150~2500 | |

| Test pressure(Mpa) | Strength test | 1.5×PN | |

| Sealing test | 1.1×PN | ||

| Air pressure seal test | 0.6MPa | ||

| Working temperature | -196℃~180℃ | ||

| Working medium | Water, oil products, natural gas, corrosive media, etc | ||

| Pressure range | 1.6~10.0MPa | CLASS 150~600 | |||

| Nominal diameter range | 15~200mm | 1/2"~8" | |||

|

Driving mode And scope of application |

Handle drive | 1.6~10.0MPa | CLASS 150~600 | ||

| 15~200mm | 1/2"~8" | ||||

| Worm gear | PN1.6~4.0MPa | PN6.4~10.0MPa | CLASS 150~300 | CLASS 400~600 | |

| Drive | 150~200 | 80~100 | 6"~8" | 3"~4" | |

| Pneumatics | 1.6~10.0MPa | CLASS 150~600 | |||

| Hydraulic | 15~200mm | 1/2"~8" | |||

| Electric |

1.6~4.OMPa DN50~200 |

6.4~10.OMPa DN50~100 |

CLASS 150~300 2"~8" |

CLASS 400~600 2"~4" |

|