Product structure characteristics

Hard seal valves are mainly used in natural gas, oil products, chemical industry, metallurgy, urban construction, environmental protection, pharmaceutical, food and other industries. Sulfur resistant series products are suitable for long-distance natural gas pipelines with hydrogen sulfide medium, many impurities and serious corrosion.

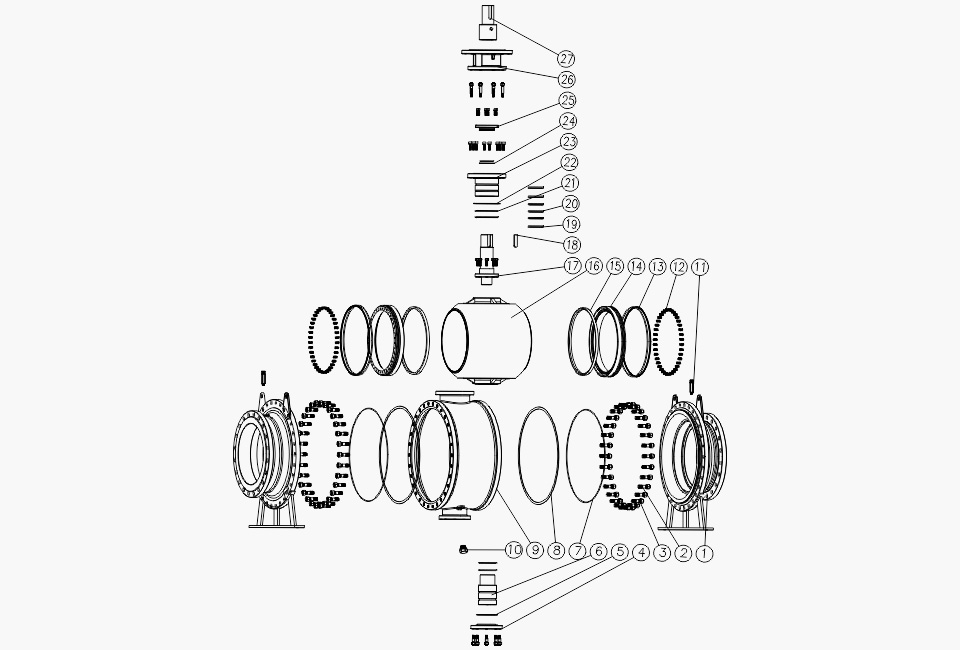

The structural characteristics of series stationary ball valves are as follows:

★ The valve body of hard seal ball valve with shell structure can be designed into three types: cast structure, forged structure and fully welded structure according to the user's needs and actual working conditions. The fully welded ball valve is mainly suitable for underground use.

★ The unique valve seat sealing structure hard seal ball valve selects the front ball sealing structure, back ball sealing structure or front ball back double sealing structure according to the pressure, medium properties and sealing requirements.

★ When the cavity pressure in the automatic pressure relief structure increases abnormally, the ball valve with single seal structure has automatic pressure relief function, while the ball valve with double seal structure is relieved by the additional pressure relief device on the valve body.

★ The sealing grease injected through the grease injection valve can play an instantaneous sealing role in case of leakage caused by damage to the emergency valve seat and valve stem seal.

★ The ball valve can be designed as a fire-proof structure according to the working conditions and the needs of users. The fire resistance design of the ball valve is in accordance with the provisions of API 607 and JB / t6899. In case of fire damage to the soft sealing ring, the fire protection structure of the ball valve can prevent a large number of medium leakage and further expansion of the fire.

★ When operating the valve, due to the friction between the ball and the valve seat, electrostatic charges will be generated and accumulated on the ball. In order to prevent electrostatic sparks, an anti-static device is set on the valve to export the charges accumulated on the ball.

★ When the valve is closed, the upstream and downstream valve seats block the flow, and the stagnant matter in the middle cavity of the valve body can be discharged through the discharge device.

★ Locking device The design of a lockable structure at the full open and full close positions of the manual ball valve can prevent the improper operation and unexpected vibration of the circuit, especially in the production line of petroleum and chemicals with natural medium, and the outdoor piping of the valve, the advantages and practical effect of this design are particularly good.

★ In order to meet the different needs of users, the company's ball valve products have two series of full diameter and reduced diameter. The channel inner diameter of full-diameter ball valve is consistent with the pipe inner diameter, which is convenient for management and cleaning. The weight of reduced diameter series ball valve is relatively light, but the fluid resistance is only about 1 / 7 of the same diameter stop valve, so the application prospect of reduced diameter series ball valve is broad.

Note: the material of sulfur resistant valve is GB (1Cr18Ni9), ASTM (a276-321), and the material of sulfur resistant valve is GB (1Cr18Ni9, CF8 + Ni.P), ASTM (a182-304, CF8 + Ni.P)

The materials of main parts and sealing surfaces of series valves can be designed and selected according to actual working conditions or special requirements of users.