working principle

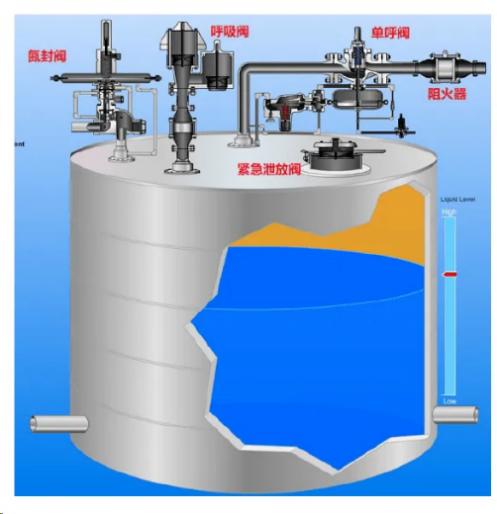

The nitrogen sealing system consists of nitrogen sealing valve, breathing valve (including flame arrester), nitrogen relief valve, emergency relief device (pressure relief valve, pressure relief manhole).

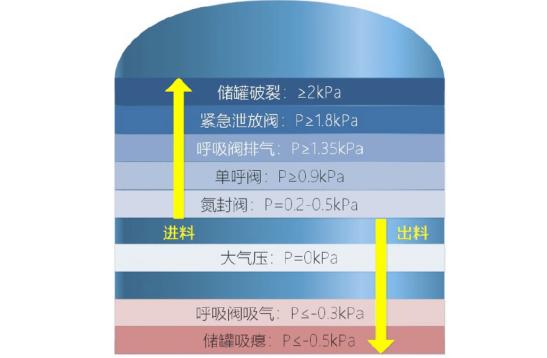

When the liquid inlet valve of the storage tank is opened to add materials to the tank, the liquid level rises, the gas phase space decreases, and the pressure in the tank rises. When the pressure in the tank is higher than the set value of the nitrogen relief valve pressure, the nitrogen relief valve opens to release nitrogen to the outside world. When the pressure in the tank drops to the set value of the nitrogen relief valve pressure, the nitrogen relief valve automatically closes.

When the liquid outlet valve of the storage tank is opened to output materials, the liquid level inside the tank decreases, the volume of the gas phase increases, and the gas phase pressure inside the tank decreases. At this time, the nitrogen sealing valve opens, injecting nitrogen into the storage tank. When the pressure inside the tank rises to the set value of the nitrogen sealing valve pressure, the nitrogen sealing valve automatically closes.

When the nitrogen sealing valve and nitrogen relief valve fail, the breathing valve replaces the nitrogen sealing valve and nitrogen relief valve to play a protective role.

The emergency relief device is used to exhale outside the tank in the event of a fire, to prevent damage to the tank due to overpressure.

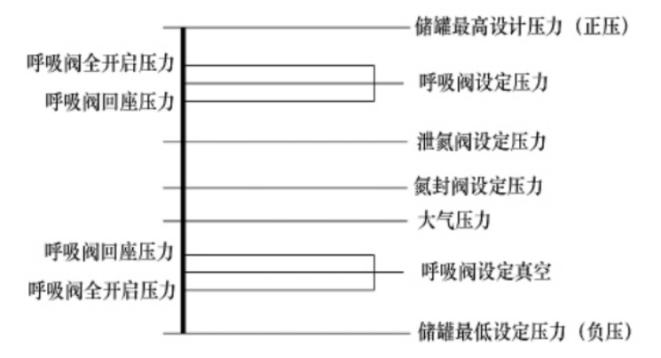

Principle of pressure setting for nitrogen sealing system

Nitrogen sealing system device

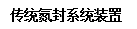

Compared to traditional nitrogen sealing system devices, Jinzi Industry utilizes its unique product (constant pressure breathing valve) to integrate the breathing valve and gas sealing device into an integrated product, while meeting the functions of nitrogen sealing and breathing, demonstrating unique advantages:

1) Due to the absence of secondary piping and control piping, the piping space is relatively wide.

2) As long as there is an empty breather valve on the storage tank, it can be set.

3) As there is no need for secondary piping and control piping engineering, it can save piping costs.

4) When installing on existing storage tanks, there is no need to add secondary piping and control piping connections.

5) Due to the use of clean pipe fittings, the structure is simple and easy to disassemble and inspect.